- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

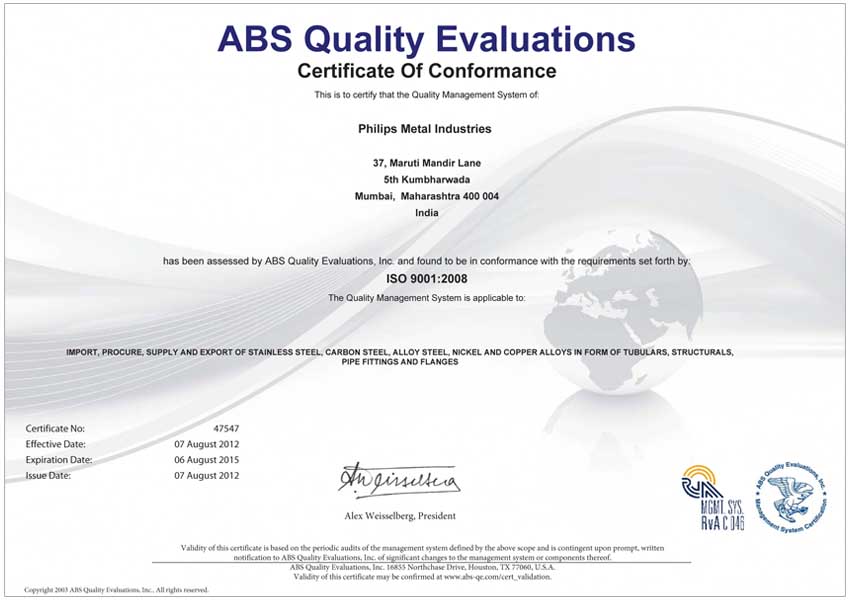

“Customer Satisfaction is our Goal. We will strive to delivery error-free, competitive, high quality products & services on time to meet & exceed our customers expectations. Our services will be continuously improved to increase Customer Competitiveness and move PHILIPS METAL INDUSTRIES towards long term economical development forwarded by optimization of resources. ”

QUALITY TESTING :