- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

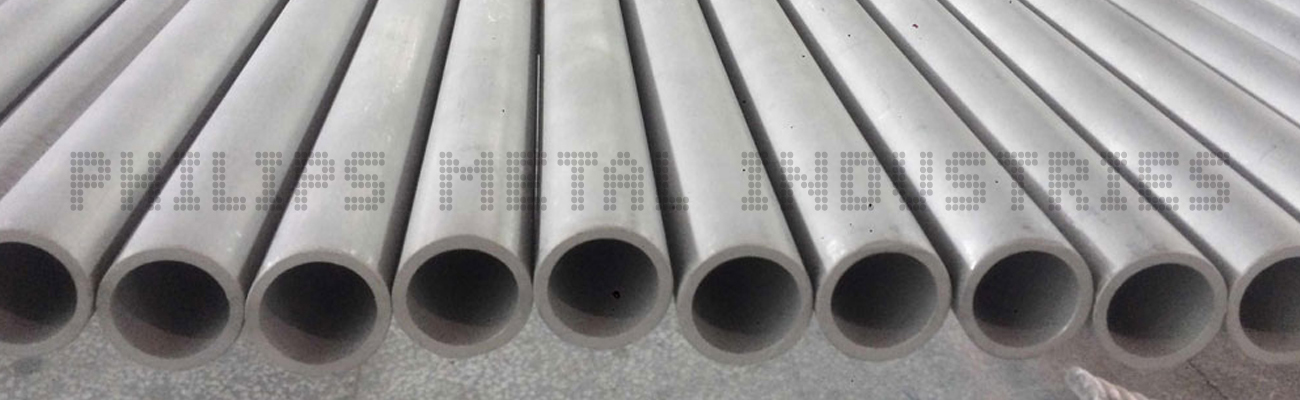

Philips Metal Industries is a manufacturer, stockiest, and exporter of high quality Stainless Steel IBR Pipes & Tubes. Premium raw materials are used in the manufacturing of IBR Pipes & Tubes. We looked into the attributes and used contemporary machinery to make these things. Depending on the needs of the customer, these pipes and tubes are offered in a variety of thicknesses, sizes, and specifications. These IBR Pipes and Tubes are utilized in many different industries, including water treatment, desalination, petrochemical, oil and gas, shipbuilding, nuclear power plants, fertilizer plants, and the chemical sector.

The Indian Boiler Regulation (IBR) establishes the material grades, pressure classifications, and dimensions that must be adhered to while producing various IBR tubing and piping materials in India. The American Society of Mechanical Engineers (ASME) outlines the essential rules which the industry must follow. It is possible to create an IBR pipe out of carbon steel, manganese steel, molybdenum steel, or chromium-molybdenum steel. The nominal pipe sizes for these pipes range from 1/2NB to 24NB. Carbon, silicon, manganese, phosphorus, and sulphur are all contained in the normal chemical makeup of IBR Pipe Material. Less than 0.35% of the substance should be carbon-based. The IBR Tube has excellent strength and versatility for a wide range of uses. Excellent tensile strength characterizes these tubes. Sizes ranging from 6.35mm OD to 254mm OD are offered. A minimum yield strength of 205 MPa and a minimum tensile strength of 415 MPa are built into the IBR tube material. They have outstanding 30% elongation characteristics. In Mumbai, we are the top providers of IBR pipes. We are committed to providing premium products at the most affordable prices.

The IBR Seamless Pipe is extremely sturdy due to the manufacturing method. These pipes can resist temperatures of up to 454 °C and pressures of up to 2900 psi. Both high-pressure and low-pressure applications make extensive use of IBR boiler tubes. The water used to create steam in these tubes may hold almost five gallons. Low-pressure systems with a capacity of less than 25 liters employ non-IBR tubes. Steam exits the boiler by a steam mover and enters the IBR Steam Pipe. These pipes can hold steam at pressures up to 3.5 kg cm^3 above atmospheric pressure and have an interior diameter greater than 254 mm. Numerous gas pipelines, drinking water pipes, chemical systems, etc. all make extensive use of the IBR Pipe Line. We produce the IBR Grade Pipe and our other products using the best raw materials and the most recent technologies.

MTC offered to the buyers-

According to EN 10204/3.1b, purchasers can get mill or manufacturer test certification. In addition, the TC includes a 100% radiography test report, a third-party test report, and a raw material certificate.

Documents offered-

Buyers are given with a fumigation certificate, commercial invoice, heat treatment chart, packaging list, QAP, material traceability report, and raw material test report.

Delivering and packaging-

The delivery of Stainless Steel Pipes is done on schedule, but only if the goods are in stock. If the product is not available in sufficient quantities, delivery time is determined by the production of SS pipes. To ensure damage-free delivery, pipes should be packaged in hardwood cases/pallets, among other things.

| Specifications | ASTM A312 / A213 |

| Pipe Size | 1/8″NB TO 30″NB IN |

| Tubes Size | 6.35mm OD upto 254mm OD in 0.6 to 20mmthk. |

| Schedule | SCH 20, SCH 30, SCH 40, STD, SCH 60, SCH 80, SCH 120, SCH 140, SCH 160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Length | Single Random, Double Random & Cut Length |

| End | Beveled End, Plain End |

| Processing Service | Punching, Bending, Welding, Decoiling, Cutting, Moulding |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Stainless Steel IBR Pipes | Stainless Steel Seamless IBR Pipes & Tubes |

| SS IBR Pipes | SS Seamless IBR Tubes |

| SS IBR Pipes & Tubes | SS IBR Tubes |

| SS Seamless IBR Pipes | Stainless Steel IBR Tubes |

| ASTM A 213 Stainless Steel IBR Pipes & Tubes | ASTM A 312 SS Seamless IBR Pipes & Tubes |

Such testing is as mentioned here –

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

ss pipes exporter, jindal ss 304 pipes price list, stainless steel 304 instrumentation tube, stainless steel pipe aisi 304, stainless steel 304 pipe thickness, 304 stainless steel pipe weight per foot, ss tubes supplier, jindal stainless steel 304 pipe price, ss tubing manufacturer, stainless steel 304h welded pipe exporter in india, stainless steel 304 tube pipe, 304l stainless steel tubing distributor, stainless steel 304h pipe manufacturer, 304 stainless steel pipe cost, stainless steel 304 pipe sizes, stainless steel 304l erw tube, 304l stainless steel pipe schedule, stainless steel 304 efw pipe manufactures in mumbai, ss 304h welded tube, ss 304 pipe price per kg in india, 304l schedule 10 stainless steel pipe, stainless steel 304 tube sizes, ss 304 tube price, ss 304l erw pipe, stainless steel pipe 304 grade weight per meter, ss 304h seamless pipes, stainless steel 304 pipe manufacturers india, stainless steel 304 pipe weight per meter, 304l stainless steel pipe dimensions , 304l stainless steel pipe pressure rating, 304 stainless steel rectangular tubes stockist , stainless steel 304 pipe schedule, stainless steel 304 pipe weight, stainless steel 304 pipe price per kg in india, stainless steel 304 square tube, stainless steel 304 seamless tubes, stainless steel pipe 304 grade, stainless steel 304 tube suppliers, 304 stainless steel tube specifications, stainless steel 304h seamless tube.