- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

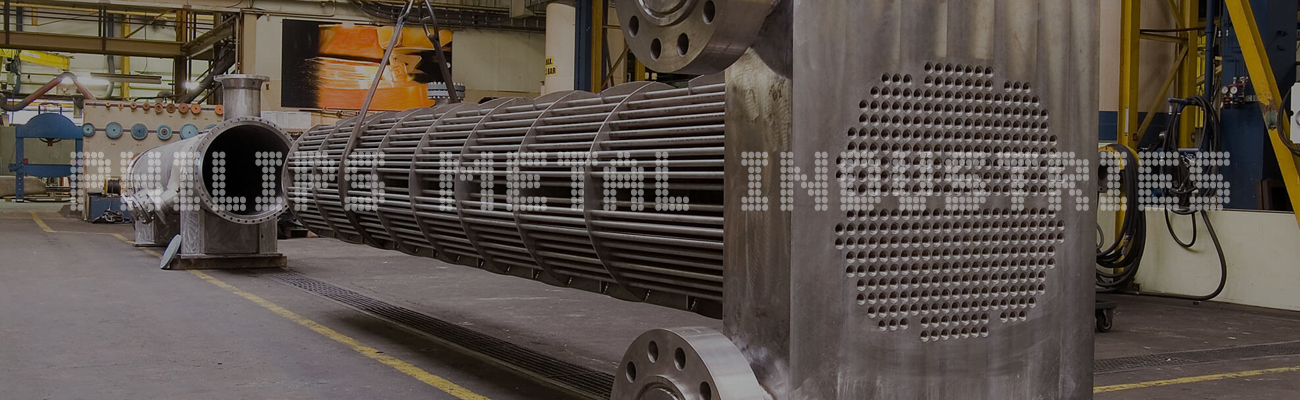

Philips Metal Industries is a trusted stockiest, manufacturer, exporter, and supplier of high quality Stainless Steel 310H Heat Exchanger Tubes that are intended to meet national and international raw material standards. A good number of industries, including chemical processing, oil and hydrocarbon processing, nuclear power generation, and aerospace, use SS 304H heat exchanger tubes. Features including smooth finishing, corrosion resistance, trouble-free installation, and dimensional accuracy make SS 304H Seamless Heat Exchanger Tubes suitable. With the help of our knowledgeable staff, Philips Metal is able to provide 304H Heat Exchanger Tubes for our valued customers that fully satisfy their requirements in terms of delivery, specs, and cost.

The manufacturer of heat exchanger tubes greatly like SS 310H due to its high carbon content. Thanks to its good qualities and great power of tolerance, the grade is appropriate for applications at high temperatures. It is also appropriate for usage in environments with sulfur dioxide gas and has good resistance to oxidation at elevated temperatures. Unfortunately, the precipitation of carbide makes the grade unsuitable for continued usage at high temperatures. Chemical elements include silicon, carbon, manganese, nickel, chromium, and silicon aid in giving the grade its mechanical and physical characteristics.

We guarantee timely delivery of all necessary materials to the client's designated location without sacrificing the SS 310H Heat Exchanger / Condenser Tubes' quality. Any type of product design can be used to provide the greatest items to customers. When determining costs, grade features, designations, and processing differences are considered. All necessary documentation and test certifications are included in the package. In addition to personalizing the outcome, we ensure that all procedural duties are completed safely and effectively.

Our business has all of the necessary delivery trucks to deliver your order right to your house, place of business, industry, or other location. We also provide additional post-purchase products that can ultimately result in cost savings for you.

| Specifications | ASTM, ASME, DIN EN, JIS ( JAPAN ), NF ( AFNOR ) |

| Range | 6.35 Mm OD to 273 Mm OD |

| Outer Diameter | 9.52 mm O.D to 50.80 mm O.D |

| Thickness | 0.7 mm to 3.68 mm |

| Schedules | 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH |

| Type | Seamless Tubes, Welded Tubes |

| Length | Up to 30mtr long |

| Finishing | It can be supplied in mechanical polished with various grits like at 80, 120, 240, 320, 400, 600 grits and mirror polished. |

| Wall thickness in mm. | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.6 | 3 | 3.2 | 3.6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O.D. in mm. | Weight in kg/meter | |||||||||||

| 6 | 0.069 | 0.081 | 0.093 | 0.104 | 0.125 | 0.144 | 0.176 | – | – | – | – | – |

| 9.52 | 0.112 | 0.134 | 0.154 | 0.174 | 0.213 | 0.249 | 0.317 | – | – | – | – | – |

| 10 | 0.119 | 0.141 | 0.163 | 0.184 | 0.225 | 0.264 | 0.336 | – | – | – | – | – |

| 12.7 | 0.153 | 0.182 | 0.21 | 0.238 | 0.293 | 0.345 | 0.444 | – | – | – | – | – |

| 14 | 0.169 | 0.201 | 0.233 | 0.264 | 0.325 | 0.384 | 0.496 | – | – | – | – | – |

| 15.87 | 0.192 | 0.229 | 0.266 | 0.301 | 0.372 | 0.44 | 0.571 | 0.694 | – | – | – | – |

| 19 | 0.231 | 0.276 | 0.32 | 0.364 | 0.45 | 0.534 | 0.696 | 0.85 | 1.066 | 1.2 | 1.264 | – |

| 25 | 0.306 | 0.366 | 0.425 | 0.484 | 0.6 | 0.714 | 0.936 | 1.15 | 1.456 | 1.65 | 1.744 | 1.926 |

| 25.4 | 0.311 | 0.372 | 0.432 | 0.492 | 0.61 | 0.726 | 0.952 | 1.17 | 1.482 | 1.68 | 1.776 | 1.962 |

| 31.8 | – | – | – | – | – | 0.918 | 1.208 | 1.49 | 1.898 | 2.16 | 2.288 | 2.538 |

| 38 | – | – | – | – | – | 1.104 | 1.456 | 1.8 | 2.301 | 2.625 | 2.784 | 3.096 |

| 44.5 | – | – | – | – | – | 1.299 | 1.716 | 2.125 | 2.724 | 3.113 | 3.304 | 3.681 |

| 50.8 | – | – | – | – | – | 1.488 | 1.968 | 2.44 | 3.133 | 3.585 | 3.808 | 4.248 |

| 63.5 | – | – | – | – | – | – | 2.476 | 3.075 | 3.959 | 4.538 | 4.824 | 5.391 |

| 76.1 | – | – | – | – | – | – | 2.98 | 3.705 | 4.778 | 5.483 | 5.832 | 6.525 |

| 101.6 | – | – | – | – | – | – | 4 | 4.98 | 6 | 7 | 7,872 | 8.82 |

| STANDARD | UNS | WERKSTOFF NR. |

| SS 310H | S31009 | - |

| SS | 310H |

| Ni | 19 - 22 |

| Fe | Balance |

| Cr | 24 – 26 |

| C | 0.040 - 0.10 |

| Si | 0.75 |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Grade | 310H |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 95 |

| Brinell (HB) max | 217 |

| Quantity | Thermal expansion | Thermal conductivity | Specific heat | Melting temperature | Service temperature | Density | Resistivity |

| Value | 16 – 17 | 16 – 16 | 500 – 500 | 1370 – 1400 | 0 – 500 | 8000 – 8000 | 0.7 – 0.7 |

| Unit | e-6/K | W/m.K | J/kg.K | °C | °C | kg/m3 | Ohm.mm2/m |

| Stainless Steel 310H Heat Exchanger Tubes | Stainless Steel 310H Seamless Heat Exchanger Tubes |

| SS 310H Heat Exchanger Tubes | SS 310H Seamless Heat Exchanger Tubes |

| 310H Heat Exchanger Tubes | ASME SS 310H Heat Exchanger Tubes |

| Steel 310H Heat Exchanger Tubes | DIN Stainless Steel 310H Heat Exchanger Tubes |

| ASTM A 213 Stainless Steel 310H Heat Exchanger Tubes | ASTM A 269 SS 310H Seamless Heat Exchanger Tubes |

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

ASTM A 213 Stainless Steel Heat Exchanger Tubes, TP 410 SS Heat Exchanger Tubes Exporter, Stainless Steel Heat Exchanger Tubes Stockist, AISI Stainless Steel Heat Exchanger Tubes Supplier, SS U-Tube Heat Exchangers, Heat Exchanger Tubes Manufacturer, ASTM A 269 SS Seamless Heat Exchanger Tubes Exporter, Steel Heat Exchanger Tubes, Heat Exchanger Tubes Suppliers, ASME SS Heat Exchanger Tubes Stockist,SS Heat Exchanger Tubes, Heat Exchanger Tubes, Heat Exchanger Tubing, Stainless Steel 321/321H Heat Exchanger Tubing, 347H SS EFW Heat Exchanger Tubes, SS Welded Heat Exchanger Tubes, Steel Heat Exchanger Tubes