- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

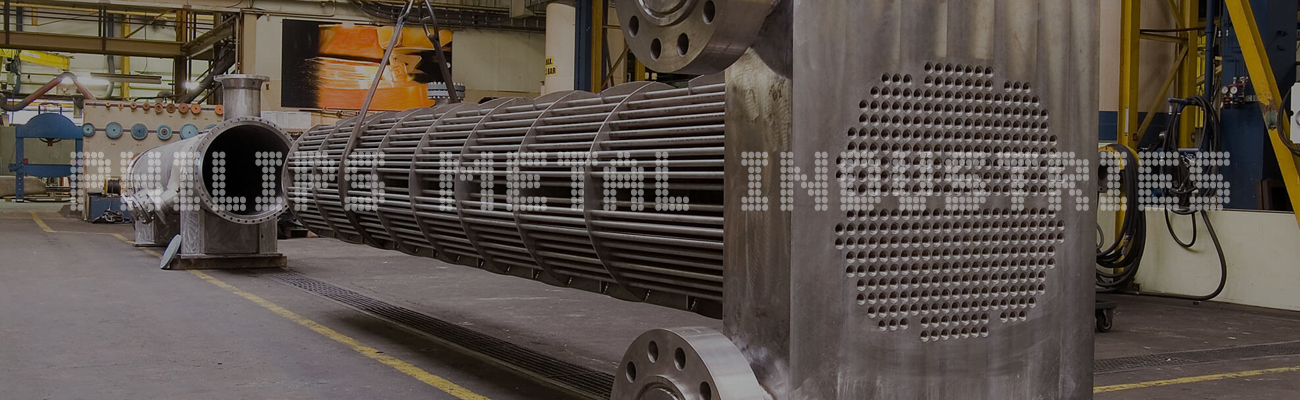

Philips Metal Industries is India's largest manufacturer and supplier of SS 317/317L high-temperature heat exchanger pipes. We stock and transport SS 317/317L pipes for heat exchangers in annealed and pickled condition, with sizes ranging from 6mm OD to 24″ OD and thicknesses up to 30mm. AISI 317/317L stainless steel pipes are available in 5.5 to 6.5 MTR and custom lengths. Stainless steel 317/317L heat exchanger pipes and tubes typically sell for Rs. 540/kg on average. Due to increased production costs, larger sizes (above 4′′) and smaller sizes (below 11/2′′) are sold at a modest premium. We at Philips Metal promise to give you the best deals from our 300+ tons of stainless steel 317/317L tubing in stock. Often utilized in the production of high temperature heat exchanger equipment are 317/317L seamless tubes.

We are a major manufacturer and supplier of 317L stainless steel tubes (seamless and welded) for all heat exchanger applications, including coolers, condensers, evaporators, preheaters, reheaters, rebuilders, steam generators, and air coolers. Heat exchanger tubes are used to make heat exchangers, which transmit heat from one fluid/medium to another. We offer heat exchanger tubes to a variety of industries, including chemicals, oil and gas, power generation, energy, and pharmaceuticals. Heat exchanger tubes come in three different varieties finned, U-bend, and straight. A part of a heat exchanger that moves heat between two fluids that is placed inside a cylinder is called a heat exchanger tube.

Alloy 317LMN and 317L are austenitic stainless steel tubes that contain molybdenum and have a significantly higher resistance to chemical degradation than traditional chromium-nickel austenitic stainless steel pipes like Alloy 304. Moreover, at higher temperatures than traditional stainless steels, 317LMN and 317L alloys provide greater creep, stress-to-rupture, and tensile strengths. All of them are "L" or low carbon grades, which offer protection against sensitization during hot procedures like welding. Compared to 304L and 316L stainless steels, austenitic stainless steel grade 317L offers better corrosion resistance. Because of the low carbon content, welding and other thermal processes can be performed without sensitization.317L is not magnetic when it is annealed, but welding may cause it to become mildly magnetic.

Our business has all of the necessary delivery trucks to deliver your order right to your house, place of business, industry, or other location. We also provide additional post-purchase products that can ultimately result in cost savings for you.

| Specifications | ASTM, ASME, DIN EN, JIS ( JAPAN ), NF ( AFNOR ) |

| Range | 6.35 Mm OD to 273 Mm OD |

| Outer Diameter | 9.52 mm O.D to 50.80 mm O.D |

| Thickness | 0.7 mm to 3.68 mm |

| Schedules | 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH |

| Type | Seamless Tubes, Welded Tubes |

| Length | Up to 30mtr long |

| Finishing | It can be supplied in mechanical polished with various grits like at 80, 120, 240, 320, 400, 600 grits and mirror polished. |

| Wall thickness in mm. | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.6 | 3 | 3.2 | 3.6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O.D. in mm. | Weight in kg/meter | |||||||||||

| 6 | 0.069 | 0.081 | 0.093 | 0.104 | 0.125 | 0.144 | 0.176 | – | – | – | – | – |

| 9.52 | 0.112 | 0.134 | 0.154 | 0.174 | 0.213 | 0.249 | 0.317 | – | – | – | – | – |

| 10 | 0.119 | 0.141 | 0.163 | 0.184 | 0.225 | 0.264 | 0.336 | – | – | – | – | – |

| 12.7 | 0.153 | 0.182 | 0.21 | 0.238 | 0.293 | 0.345 | 0.444 | – | – | – | – | – |

| 14 | 0.169 | 0.201 | 0.233 | 0.264 | 0.325 | 0.384 | 0.496 | – | – | – | – | – |

| 15.87 | 0.192 | 0.229 | 0.266 | 0.301 | 0.372 | 0.44 | 0.571 | 0.694 | – | – | – | – |

| 19 | 0.231 | 0.276 | 0.32 | 0.364 | 0.45 | 0.534 | 0.696 | 0.85 | 1.066 | 1.2 | 1.264 | – |

| 25 | 0.306 | 0.366 | 0.425 | 0.484 | 0.6 | 0.714 | 0.936 | 1.15 | 1.456 | 1.65 | 1.744 | 1.926 |

| 25.4 | 0.311 | 0.372 | 0.432 | 0.492 | 0.61 | 0.726 | 0.952 | 1.17 | 1.482 | 1.68 | 1.776 | 1.962 |

| 31.8 | – | – | – | – | – | 0.918 | 1.208 | 1.49 | 1.898 | 2.16 | 2.288 | 2.538 |

| 38 | – | – | – | – | – | 1.104 | 1.456 | 1.8 | 2.301 | 2.625 | 2.784 | 3.096 |

| 44.5 | – | – | – | – | – | 1.299 | 1.716 | 2.125 | 2.724 | 3.113 | 3.304 | 3.681 |

| 50.8 | – | – | – | – | – | 1.488 | 1.968 | 2.44 | 3.133 | 3.585 | 3.808 | 4.248 |

| 63.5 | – | – | – | – | – | – | 2.476 | 3.075 | 3.959 | 4.538 | 4.824 | 5.391 |

| 76.1 | – | – | – | – | – | – | 2.98 | 3.705 | 4.778 | 5.483 | 5.832 | 6.525 |

| 101.6 | – | – | – | – | – | – | 4 | 4.98 | 6 | 7 | 7,872 | 8.82 |

| STANDARD | UNS | WNR. | EN | JIS |

|---|---|---|---|---|

| SS 317 | S31700 | 1.4449 | - | SUS 317 |

| SS 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 317L |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| 317 | 0.08 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 14 | - |

| 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 15 | - |

| Density | 8.0 g/cm3 |

|---|---|

| Melting Point | 1454 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Physical Properties (Room Temperature) | ||

|---|---|---|

| Specific Heat (0-100°C) | 500 | J.kg-1.°K-1 |

| Thermal Conductivity | 14.6 | W.m -1.°K-1 |

| Thermal Expansion | 16.5 | mm/m/°C |

| Modulus Elasticity | 193 | GPa |

| Electrical Resistivity | 7.4 | μohm/cm |

| Density | 7.99 | g/cm3 |

| Stainless Steel 317 Heat Exchanger Tubes | Stainless Steel 317L Seamless Heat Exchanger Tubes |

| SS 317L Heat Exchanger Tubes | SS 317 Seamless Heat Exchanger Tubes |

| 317 Heat Exchanger Tubes | ASME SS 317 Heat Exchanger Tubes |

| Steel 317L Heat Exchanger Tubes | DIN Stainless Steel 317L Heat Exchanger Tubes |

| ASTM A 213 Stainless Steel 317 Heat Exchanger Tubes | ASTM A 269 SS 317L Seamless Heat Exchanger Tubes |

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

ASTM A 213 Stainless Steel Heat Exchanger Tubes, TP 410 SS Heat Exchanger Tubes Exporter, Stainless Steel Heat Exchanger Tubes Stockist, AISI Stainless Steel Heat Exchanger Tubes Supplier, SS U-Tube Heat Exchangers, Heat Exchanger Tubes Manufacturer, ASTM A 269 SS Seamless Heat Exchanger Tubes Exporter, Steel Heat Exchanger Tubes, Heat Exchanger Tubes Suppliers, ASME SS Heat Exchanger Tubes Stockist,SS Heat Exchanger Tubes, Heat Exchanger Tubes, Heat Exchanger Tubing, Stainless Steel 321/321H Heat Exchanger Tubing, 347H SS EFW Heat Exchanger Tubes, SS Welded Heat Exchanger Tubes, Steel Heat Exchanger Tubes