- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

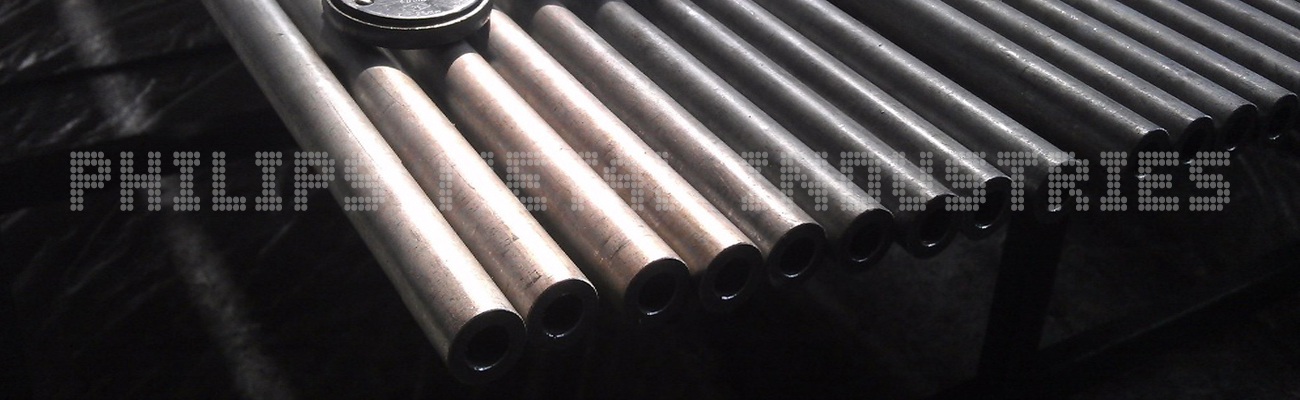

Philips Metal Industries manufactures a comprehensive range of stainless steel products that meet various standards and specifications. Stainless Steel 316TI Condenser Tubes are made in conformity with internationally recognized standards. After verifying the customer's specifications, we start manufacturing the tubes. Condenser tube manufacturing is carried out under the guidance of experts. To achieve the highest level of tube workability, we exclusively choose premium raw materials. Numerous noteworthy characteristics of SS condenser tubes make them appropriate for a wide range of industrial applications. Furnished surface and dimensional precision can be obtained with a variety of trending machines.

With titanium grade stability, alloy 316Ti is used. It belongs to the 300 molybdenum bearing austenitic stainless steel grade series. Another name for it is NO. 1.4571 grades. Excellent resistance to both local and overall corrosion is provided by this metal. In situations with large concentrations of reducing elements, it is susceptible to pitting and crevice corrosion cracking. It is superior to a standard grade of nickel and chromium with molybdenum added. Grain boundary precipitation or sensitization can occur in this alloy. Even at these high temperatures, it has excellent thermal stability. Its cubic structure is face-centered. The cold working activities harden the grade without exposing it to the heat treatment process. It also goes through the industrial finishing process to achieve surface polish and dimensional correctness. It is coated in SATIN, and additional oxidation protection is provided by a striking black finish.

Testing guarantees that the product will perform properly and be durable while maintaining design correctness, corrosion resistance, tensile strength, and yield strength. We adhere to safe handling guidelines while conducting tests on products of any size, including nondestructive testing (NDT) and the electro spot method. Material testing becomes more likely in order to reduce the possibility of unanticipated mistakes in the design or fabrication process. So, the testing eliminates the single predicted or unexpected flaw from the final product. Industry makes sure that every customer receives the necessary test certificates for the tests conducted on them in order to verify the quality of the manufactured product on an individual basis.

We attach manufacturing test certificates to our items that satisfy globally accepted standards. They consist of the following: the MTC report compliant with EN 10204 3.1 or 3.2, the test reports for raw materials and mills, the NABL test report, the signed certificate from us, and the quality assurance plan. Other emphasized documents include the specification guide, welding guide, disinfection certifications, invoice, and packing information list.

| Specifications | ASTM A213, ASTM A312, ASTM A269 |

| Seamless Pipes Size | Outer diameter: 4 to 219mm Wall Thickness: 0.5 to 20mm |

| Welded Pipe Size | Outer Diameter: 5.0 - 1219.2 mm |

| EFW Pipe Size | Outer Diameter: 5.0 - 1219.2 mm |

| Wall thickness | SCH5, SCH 40, SCH 10, SCH 80, SCH 160, SCH 80S, SCH XXS, SCH XS |

| Length | Double Random & Required Length End, Single Random, Plain End, Treaded, Beveled End |

| Form | Round, Square, Rectangular |

| Condition | Hot Finished, Annealed and Pickled, Bright Annealed, Polished, Cold Drawn |

| END | Beveled End, Plain End, Treaded |

| Techniques | EFW/ Seamless / ERW / Welded / LSAW/ Fabricated / Seam-Welded / CDW/ Redrawn |

| Packing | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers' request |

| Sizes in | Sizes in Inches | Sizes in Decimal |

| 7.94 | 5/16 | .3125 |

| 3.18 | 1/8 | .1250 |

| 4.76 | 3/16 | .1875 |

| 50.80 | 2 | 2.00 |

| 1.59 | 1/16 | .0625 |

| 38.10 | 1 1/2 | 1.50 |

| 6.35 | 1/4 | .2500 |

| 19.05 | 3/4 | .7500 |

| 14.29 | 9/16 | .5625 |

| 31.75 | 1 1/4 | 1.25 |

| 9.53 | 3/8 | .3750 |

| 11.11 | 7/16 | .4375 |

| 12.70 | 1/2 | .5000 |

| 23.81 | 15/16 | .9375 |

| 15.88 | 5/8 | .6250 |

| 17.46 | 11/16 | .6875 |

| 20.64 | 13/16 | .8125 |

| 22.23 | 7/8 | .8750 |

| 25.40 | 1 | 1.00 |

| Gauge | Typical Value in Inch | Thickness Range in Inch |

|---|---|---|

| 19 | 0.042 | 0.038 through 0.042 |

| 11 | 0.12 | 0.112 through 0.122 |

| 17 | 0.058 | 0.053 through 0.058 |

| 15 | 0.072 | 0.066 through 0.074 |

| 20 | 0.035 | 0.031 through 0.035 |

| 22 | 0.028 | 0.025 through 0.029 |

| 10 | 0.134 | 0.126 through 0.136 |

| 18 | 0.049 | 0.044 through 0.049 |

| 12 | 0.109 | 0.101 through 0.111 |

| 9 | 0.148 | 0.140 through 0.150 |

| 16 | 0.065 | 0.060 through 0.065 |

| 13 | 0.095 | 0.087 through 0.097 |

| 14 | 0.083 | 0.075 through 0.085 |

| 8 | 0.165 | 0.157 through 0.167 |

| 7 | 0.18 | 0.175 through 0.185 |

| Pipe Size in Inches | Pipe Schedule | 500 | 100 | 300 | 200 | 400 | 600 | 700 | 650 | 750 |

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 40 | 1014 | 1531 | 1187 | 1321 | 1091 | 967 | 919 | 938 | 909 |

| 80 | 1466 | 2213 | 1715 | 1909 | 1577 | 1397 | 1328 | 1355 | 1314 | |

| 160 | 2386 | 3601 | 2791 | 3106 | 2566 | 2273 | 2161 | 2206 | 2138 | |

| 1 1/2 | 40 | 1496 | 2257 | 1750 | 1947 | 1608 | 1425 | 1354 | 1383 | 1340 |

| 80 | 2108 | 3182 | 2466 | 2744 | 2267 | 2009 | 1909 | 1949 | 1889 | |

| 160 | 3060 | 4619 | 3580 | 3984 | 3291 | 2916 | 2772 | 2829 | 2743 | |

| 2 | 40 | 1260 | 1902 | 1474 | 1640 | 1355 | 1201 | 1141 | 1165 | 1129 |

| 80 | 1820 | 2747 | 2129 | 2369 | 1957 | 1734 | 1648 | 1682 | 1631 | |

| 160 | 2980 | 4499 | 3486 | 3880 | 3205 | 2840 | 2699 | 2755 | 2671 | |

| 8 | 40 | 711 | 1073 | 832 | 926 | 765 | 678 | 644 | 657 | 637 |

| 80 | 1121 | 1692 | 1311 | 1459 | 1205 | 1068 | 1015 | 1036 | 1005 | |

| 160 | 2103 | 3175 | 2460 | 2738 | 2262 | 2004 | 1905 | 1944 | 1885 | |

| 6 | 40 | 808 | 1219 | 945 | 1052 | 869 | 770 | 732 | 747 | 724 |

| 80 | 1267 | 1913 | 1483 | 1650 | 1363 | 1208 | 1148 | 1172 | 1136 | |

| 160 | 2179 | 3289 | 2549 | 2836 | 2343 | 2076 | 1973 | 2014 | 1953 | |

| 1 | 40 | 2019 | 3048 | 2362 | 2629 | 2171 | 1924 | 1824 | 1867 | 1810 |

| 80 | 2791 | 4213 | 3265 | 3634 | 3002 | 2659 | 2528 | 2580 | 2501 | |

| 160 | 4068 | 6140 | 4759 | 5296 | 4375 | 3876 | 3684 | 3761 | 3646 | |

| 3 | 40 | 1196 | 1806 | 1400 | 1558 | 1287 | 1140 | 1084 | 1106 | 1072 |

| 80 | 1691 | 2553 | 1979 | 2202 | 1819 | 1612 | 1532 | 1564 | 1516 | |

| 160 | 2544 | 3840 | 2976 | 3312 | 2736 | 2424 | 2304 | 2352 | 2280 | |

| 5 | 40 | 889 | 1342 | 1040 | 1158 | 956 | 847 | 805 | 822 | 797 |

| 80 | 1312 | 1981 | 1535 | 1709 | 1411 | 1250 | 1189 | 1213 | 1176 | |

| 160 | 2262 | 3414 | 2646 | 2945 | 2433 | 2155 | 2049 | 2091 | 2027 | |

| 10 | 40 | 645 | 974 | 755 | 840 | 694 | 615 | 584 | 596 | 578 |

| 80 | 1066 | 1609 | 1247 | 1388 | 1147 | 1016 | 966 | 986 | 956 | |

| 160 | 2085 | 3147 | 2439 | 2714 | 2242 | 1986 | 1880 | 1927 | 1868 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 316TI | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316TI | min. | – | – | – | – | – | 16.0 | 2.0-3.0 | 10.0 | – |

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | 0.1 | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316TI | 515 | 205 | 35 | 75 | 205 |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316TI | 515 | 205 | 35 | 75 | 205 |

| Stainless Steel 316Ti Condenser Tubes | Stainless Steel 316Ti Seamless Condenser Tubes |

| SS 316Ti Condenser Tubes | SS 316Ti Seamless Condenser Tubes |

| Condenser Tubes | SS 316Ti JIS Condenser Tubes |

| SS 316Ti DIN Condenser Tubes | ASME Stainless Steel 316Ti Condenser Tubes |

| ASTM A 249 Stainless Steel 316Ti Condenser Tubes | ASTM A 249 SS 316Ti Seamless Condenser Tubes |

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

stainless steel 316 pipe thickness, ss 316ti welded tube, stainless steel 316 tube pipe, ss 316 pipe price per kg in india, jindal ss 316 pipes price list, stainless steel 316ti pipe manufacturer, 316l stainless steel pipe schedule, stainless steel 316 efw pipe manufactures in mumbai, 316l stainless steel pipe pressure rating, jindal stainless steel 316 pipe price, stainless steel 316 pipe sizes, stainless steel 316 pipe weight per meter, stainless steel pipe 316 grade, stainless steel 316 instrumentation tube, ss 316ti seamless pipes, stainless steel pipe 316 grade weight per meter, stainless steel pipe aisi 316, stainless steel 316ti seamless tube, 316l stainless steel pipe dimensions , 316 stainless steel tube specifications, stainless steel 316 pipe weight, stainless steel 316 tube suppliers, stainless steel 316 square tube, ss 316 tube price, 316l schedule 10 stainless steel pipe, stainless steel 316ti welded pipe exporter in india, stainless steel 316 pipe schedule, 316 stainless steel rectangular tubes stockist , stainless steel 316l erw tube, 316 stainless steel pipe weight per foot, stainless steel 316 pipe price per kg in india, stainless steel 316 seamless tubes, stainless steel 316 tube sizes, stainless steel 316 pipe manufacturers india, 316l stainless steel tubing distributor, ss 316l erw pipe, 316 stainless steel pipe cost.