- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

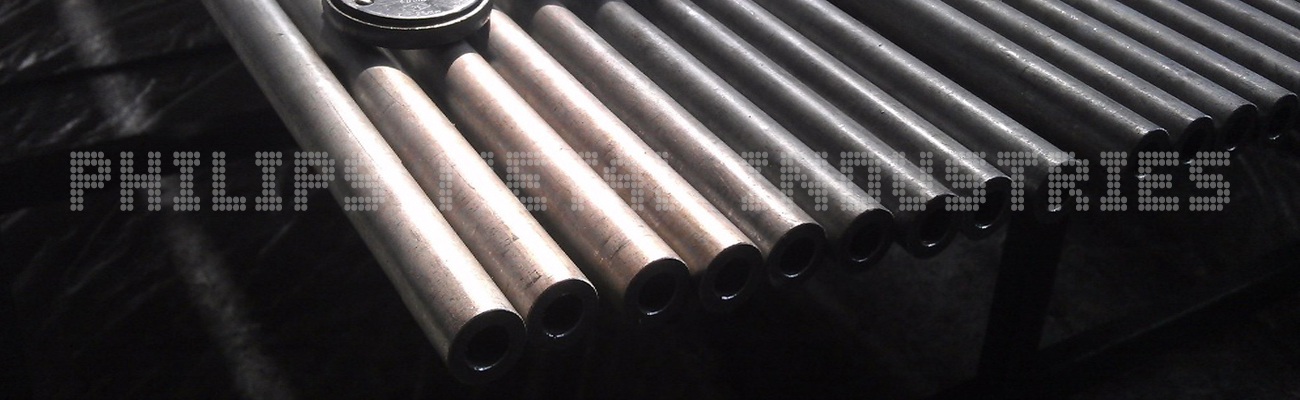

Philips Metal Industries is a leading manufacturer, exporter, stockist, and supplier of high quality Stainless Steel 321/321H Condenser Tubes that are intended to meet national and international raw material standards. The bulk of industry standard standards are covered by our diverse selection of Stainless Steel 321 Seamless Condenser Tubes. On request, we do, however, also provide SS 321 Condenser Tubes in non-standard specialized diameters. Our production schedule is made to completely satisfy consumer requests for SS 321 Seamless Condenser Tubes in terms of cost, timeliness, and details.

Heat Exchanger / Condenser SS 321/SS 321H When transporting heat between two liquids or gases that are at different temperatures, tubes are typically utilized as the element. These heat exchangers are high-performance goods made of stainless steel alloy that are primarily utilized in hot conditions. Moreover, the alloy's carbon, titanium, nickel, and chromium contents sustain this grade. The chance of carbide precipitation during welding is decreased when there is carbon content. These have better resistance to aqueous corrosion and tensile strength. The alloy SS 321/SS321H demonstrates exceptional resistance against creep and rupture. These also have a tendency to stress corrosion crack. However, these have a higher level of resistance against corrosion and metabolism. The inclusion of chromium and nickel content promotes intergranular corrosion resistance following heat treatment.

The 321 / 321H Stainless Steel Condenser Tubes are put through a variety of tests to ensure their quality. Every test is conducted while taking into account the demands and specifications of the clients, in accordance with industry standards and regulations. Tests include formability, hardness, flaring, flatness, and ultrasonic testing; third-party examination is also included. A number of other tests are conducted, including destructive, positive material identification, and pitting resistance tests.

We attach manufacturing test certificates to our items that satisfy globally accepted standards. They consist of the following: the MTC report compliant with EN 10204 3.1 or 3.2, the test reports for raw materials and mills, the NABL test report, the signed certificate from us, and the quality assurance plan. Other emphasized documents include the specification guide, welding guide, disinfection certifications, invoice, and packing information list.

| Specifications | ASTM A213, ASTM A312, ASTM A269 |

| Seamless Pipes Size | Outer diameter: 4 to 219mm Wall Thickness: 0.5 to 20mm |

| Welded Pipe Size | Outer Diameter: 5.0 - 1219.2 mm |

| EFW Pipe Size | Outer Diameter: 5.0 - 1219.2 mm |

| Wall thickness | SCH5, SCH 40, SCH 10, SCH 80, SCH 160, SCH 80S, SCH XXS, SCH XS |

| Length | Double Random & Required Length End, Single Random, Plain End, Treaded, Beveled End |

| Form | Round, Square, Rectangular |

| Condition | Hot Finished, Annealed and Pickled, Bright Annealed, Polished, Cold Drawn |

| END | Beveled End, Plain End, Treaded |

| Techniques | EFW/ Seamless / ERW / Welded / LSAW/ Fabricated / Seam-Welded / CDW/ Redrawn |

| Packing | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers' request |

| Sizes in | Sizes in Inches | Sizes in Decimal |

| 7.94 | 5/16 | .3125 |

| 3.18 | 1/8 | .1250 |

| 4.76 | 3/16 | .1875 |

| 50.80 | 2 | 2.00 |

| 1.59 | 1/16 | .0625 |

| 38.10 | 1 1/2 | 1.50 |

| 6.35 | 1/4 | .2500 |

| 19.05 | 3/4 | .7500 |

| 14.29 | 9/16 | .5625 |

| 31.75 | 1 1/4 | 1.25 |

| 9.53 | 3/8 | .3750 |

| 11.11 | 7/16 | .4375 |

| 12.70 | 1/2 | .5000 |

| 23.81 | 15/16 | .9375 |

| 15.88 | 5/8 | .6250 |

| 17.46 | 11/16 | .6875 |

| 20.64 | 13/16 | .8125 |

| 22.23 | 7/8 | .8750 |

| 25.40 | 1 | 1.00 |

| Gauge | Typical Value in Inch | Thickness Range in Inch |

|---|---|---|

| 19 | 0.042 | 0.038 through 0.042 |

| 11 | 0.12 | 0.112 through 0.122 |

| 17 | 0.058 | 0.053 through 0.058 |

| 15 | 0.072 | 0.066 through 0.074 |

| 20 | 0.035 | 0.031 through 0.035 |

| 22 | 0.028 | 0.025 through 0.029 |

| 10 | 0.134 | 0.126 through 0.136 |

| 18 | 0.049 | 0.044 through 0.049 |

| 12 | 0.109 | 0.101 through 0.111 |

| 9 | 0.148 | 0.140 through 0.150 |

| 16 | 0.065 | 0.060 through 0.065 |

| 13 | 0.095 | 0.087 through 0.097 |

| 14 | 0.083 | 0.075 through 0.085 |

| 8 | 0.165 | 0.157 through 0.167 |

| 7 | 0.18 | 0.175 through 0.185 |

| Pipe Size in Inches | Pipe Schedule | 500 | 100 | 300 | 200 | 400 | 600 | 700 | 650 | 750 |

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 40 | 1014 | 1531 | 1187 | 1321 | 1091 | 967 | 919 | 938 | 909 |

| 80 | 1466 | 2213 | 1715 | 1909 | 1577 | 1397 | 1328 | 1355 | 1314 | |

| 160 | 2386 | 3601 | 2791 | 3106 | 2566 | 2273 | 2161 | 2206 | 2138 | |

| 1 1/2 | 40 | 1496 | 2257 | 1750 | 1947 | 1608 | 1425 | 1354 | 1383 | 1340 |

| 80 | 2108 | 3182 | 2466 | 2744 | 2267 | 2009 | 1909 | 1949 | 1889 | |

| 160 | 3060 | 4619 | 3580 | 3984 | 3291 | 2916 | 2772 | 2829 | 2743 | |

| 2 | 40 | 1260 | 1902 | 1474 | 1640 | 1355 | 1201 | 1141 | 1165 | 1129 |

| 80 | 1820 | 2747 | 2129 | 2369 | 1957 | 1734 | 1648 | 1682 | 1631 | |

| 160 | 2980 | 4499 | 3486 | 3880 | 3205 | 2840 | 2699 | 2755 | 2671 | |

| 8 | 40 | 711 | 1073 | 832 | 926 | 765 | 678 | 644 | 657 | 637 |

| 80 | 1121 | 1692 | 1311 | 1459 | 1205 | 1068 | 1015 | 1036 | 1005 | |

| 160 | 2103 | 3175 | 2460 | 2738 | 2262 | 2004 | 1905 | 1944 | 1885 | |

| 6 | 40 | 808 | 1219 | 945 | 1052 | 869 | 770 | 732 | 747 | 724 |

| 80 | 1267 | 1913 | 1483 | 1650 | 1363 | 1208 | 1148 | 1172 | 1136 | |

| 160 | 2179 | 3289 | 2549 | 2836 | 2343 | 2076 | 1973 | 2014 | 1953 | |

| 1 | 40 | 2019 | 3048 | 2362 | 2629 | 2171 | 1924 | 1824 | 1867 | 1810 |

| 80 | 2791 | 4213 | 3265 | 3634 | 3002 | 2659 | 2528 | 2580 | 2501 | |

| 160 | 4068 | 6140 | 4759 | 5296 | 4375 | 3876 | 3684 | 3761 | 3646 | |

| 3 | 40 | 1196 | 1806 | 1400 | 1558 | 1287 | 1140 | 1084 | 1106 | 1072 |

| 80 | 1691 | 2553 | 1979 | 2202 | 1819 | 1612 | 1532 | 1564 | 1516 | |

| 160 | 2544 | 3840 | 2976 | 3312 | 2736 | 2424 | 2304 | 2352 | 2280 | |

| 5 | 40 | 889 | 1342 | 1040 | 1158 | 956 | 847 | 805 | 822 | 797 |

| 80 | 1312 | 1981 | 1535 | 1709 | 1411 | 1250 | 1189 | 1213 | 1176 | |

| 160 | 2262 | 3414 | 2646 | 2945 | 2433 | 2155 | 2049 | 2091 | 2027 | |

| 10 | 40 | 645 | 974 | 755 | 840 | 694 | 615 | 584 | 596 | 578 |

| 80 | 1066 | 1609 | 1247 | 1388 | 1147 | 1016 | 966 | 986 | 956 | |

| 160 | 2085 | 3147 | 2439 | 2714 | 2242 | 1986 | 1880 | 1927 | 1868 |

| STANDARD | UNS | WNR. | EN | JIS |

|---|---|---|---|---|

| SS 321 | S32100 | 1.4541 | X6CrNiTi18-10 | SUS 321 |

| SS 321H | S32109 | 1.4878 | X12CrNiTi18-9 | SUS 321H |

| % | Cr | Ni | C | Si | Mn | P | S | N | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 321 | min:17.0 max:19.0 |

min: 9.0 max:12.0 |

max:0.08 | max:0.75 | max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N) max:0.70 |

Balance |

| 321H | min:17.0 max:19.0 |

min: 9.0 max:12.0 |

min:0.04 max:0.10 |

min:18.0 max:20.0 |

max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N) max:0.70 |

Balance |

| Grade | Tensile Strength ksi (min.) |

Yield Strength 0.2% Offset ksi (min.) |

Elongation - % in 50 mm (min.) |

Hardness (Brinell) MAX |

|---|---|---|---|---|

| 321/321H | 75 | 30 | 40 | 217 |

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | |

|---|---|---|---|---|---|

| at 68 °F | at 68 – 212°F | at 68 – 1832°F | at 200°F | at 32 – 212°F | in tension (E) |

| 0.286 | 9.2 | 20.5 | 9.3 | 0.12 | 28 x 106 |

| Stainless Steel 321 Condenser Tubes | Stainless Steel 321H Seamless Condenser Tubes |

| SS 321H Condenser Tubes | SS 321 Seamless Condenser Tubes |

| Condenser Tubes | SS 321H JIS Condenser Tubes |

| SS 321 DIN Condenser Tubes | ASME Stainless Steel 321 Condenser Tubes |

| ASTM A 249 Stainless Steel 321 Condenser Tubes | ASTM A 249 SS 321H Seamless Condenser Tubes |

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

stainless steel 321 pipe sizes, 321 stainless steel pipe weight per foot, 321h stainless steel tubing distributor, stainless steel 321 tube suppliers, ss 321 tube price, stainless steel 321 pipe weight per meter, jindal stainless steel 321 pipe price, stainless steel 321 pipe schedule, stainless steel 321 pipe manufacturers india, stainless steel 321 seamless tubes, stainless steel 321 pipe manufacturer, 321 stainless steel pipe cost, ss 321h erw pipe, jindal ss 321 pipes price list, stainless steel 321 efw pipe manufactures in mumbai, 321h schedule 10 stainless steel pipe, stainless steel 321 tube pipe, stainless steel 321h erw tube, ss 321 pipe price per kg in india, 321h stainless steel pipe dimensions, stainless steel 321 pipe price per kg in india, stainless steel 321 tube sizes, stainless steel 321 pipe weight, stainless steel 321 instrumentation tube, stainless steel pipe 321 grade, sus 321 stainless steel tube specifications, 321 stainless steel rectangular tubes stockist, 321h stainless steel pipe pressure rating, stainless steel 321 pipe thickness, stainless steel 321 square tube exporter in india, stainless steel pipe aisi 321, 321h stainless steel pipe schedule, stainless steel pipe 321 grade weight per meter.