- shah@philipsmetal.com

- |

- +91-22-2382 0045 / 46 | +6610 9349

We have more than 5000 clients in more than

We have more than 5000 clients in more than

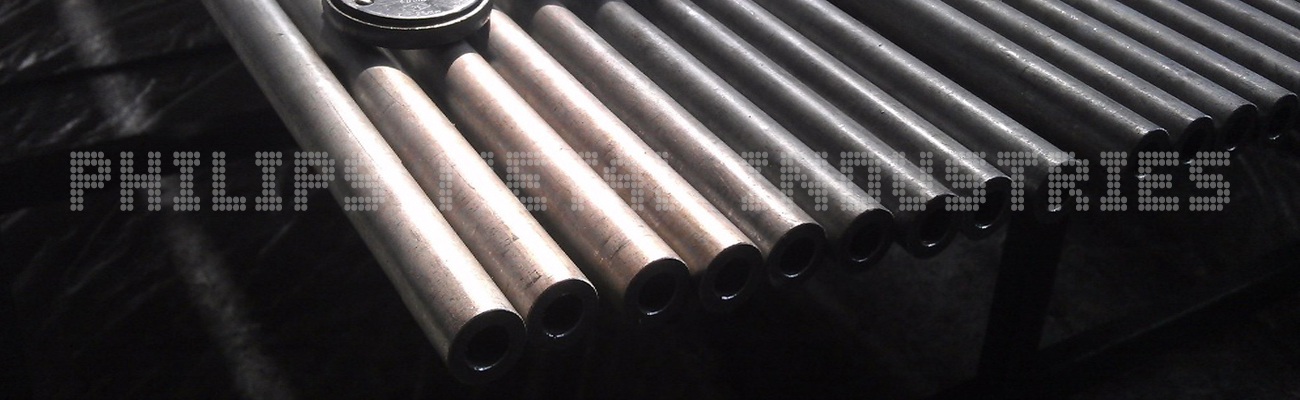

Philips Metal Industries is primarily engaged in the supply, manufacture, and export of Stainless Steel 317/317L Condenser Tubes. We attend to each and every need and want of our esteemed clients. To meet their needs, we provide a very high-quality and long-lasting standard product in custom sizes, forms, grades, and dimensions at very affordable prices. The product that we sell is made from premium raw materials that we purchased from the industry's top source. The product is manufactured in compliance with established industry rules and requirements.

Low carbon and molybdenum-containing austenitic stainless steel alloys make up Stainless Steel 317/317L Condenser Tubes. Furthermore taken into account are the contents of nickel and chromium, which are resistant to a variety of chemical assaults. Pitting, crevice corrosion, and general corrosion resistance are all demonstrated well by these alloys. In high-temperature conditions, it also provides increased creep and greater tensile strength. Particularly oxidizing to acids like nitric acid are the heat exchangers and condenser. Owing to its low carbon content, it provides exceptional resistance to welding-induced sensitization and stress rupture at elevated temperatures. On the other hand, the condenser becomes slightly magnetic after welding, but it is not magnetic when it is annealed.

Stainless steel 317, also referred to as UNS S31700, is mainly composed of high levels of carbon, phosphorous, sulphur, and other earthy chemical components, along with good quality nickel and chromium. Stainless steel 317/317L is the grade that is most typically used in welded structures. It is a low carbon variant of the material. When fabricating condenser tubes, 317 and 317L share almost identical features that are critical. Among the qualities are high toughness, pitting resistance to acidic environments and chloride, good stress to rupture ratio, high stress crack corrosion resistance, and outstanding resistance to corrosion. Both grades are suitable for the annealing process, which involves heating the material to a high temperature and quickly cooling it down.

We attach manufacturing test certificates to our items that satisfy globally accepted standards. They consist of the following: the MTC report compliant with EN 10204 3.1 or 3.2, the test reports for raw materials and mills, the NABL test report, the signed certificate from us, and the quality assurance plan. Other emphasized documents include the specification guide, welding guide, disinfection certifications, invoice, and packing information list.

| Specifications | ASTM A213, ASTM A312, ASTM A269 |

| Seamless Pipes Size | Outer diameter: 4 to 219mm Wall Thickness: 0.5 to 20mm |

| Welded Pipe Size | Outer Diameter: 5.0 - 1219.2 mm |

| EFW Pipe Size | Outer Diameter: 5.0 - 1219.2 mm |

| Wall thickness | SCH5, SCH 40, SCH 10, SCH 80, SCH 160, SCH 80S, SCH XXS, SCH XS |

| Length | Double Random & Required Length End, Single Random, Plain End, Treaded, Beveled End |

| Form | Round, Square, Rectangular |

| Condition | Hot Finished, Annealed and Pickled, Bright Annealed, Polished, Cold Drawn |

| END | Beveled End, Plain End, Treaded |

| Techniques | EFW/ Seamless / ERW / Welded / LSAW/ Fabricated / Seam-Welded / CDW/ Redrawn |

| Packing | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers' request |

| Sizes in | Sizes in Inches | Sizes in Decimal |

| 7.94 | 5/16 | .3125 |

| 3.18 | 1/8 | .1250 |

| 4.76 | 3/16 | .1875 |

| 50.80 | 2 | 2.00 |

| 1.59 | 1/16 | .0625 |

| 38.10 | 1 1/2 | 1.50 |

| 6.35 | 1/4 | .2500 |

| 19.05 | 3/4 | .7500 |

| 14.29 | 9/16 | .5625 |

| 31.75 | 1 1/4 | 1.25 |

| 9.53 | 3/8 | .3750 |

| 11.11 | 7/16 | .4375 |

| 12.70 | 1/2 | .5000 |

| 23.81 | 15/16 | .9375 |

| 15.88 | 5/8 | .6250 |

| 17.46 | 11/16 | .6875 |

| 20.64 | 13/16 | .8125 |

| 22.23 | 7/8 | .8750 |

| 25.40 | 1 | 1.00 |

| Gauge | Typical Value in Inch | Thickness Range in Inch |

|---|---|---|

| 19 | 0.042 | 0.038 through 0.042 |

| 11 | 0.12 | 0.112 through 0.122 |

| 17 | 0.058 | 0.053 through 0.058 |

| 15 | 0.072 | 0.066 through 0.074 |

| 20 | 0.035 | 0.031 through 0.035 |

| 22 | 0.028 | 0.025 through 0.029 |

| 10 | 0.134 | 0.126 through 0.136 |

| 18 | 0.049 | 0.044 through 0.049 |

| 12 | 0.109 | 0.101 through 0.111 |

| 9 | 0.148 | 0.140 through 0.150 |

| 16 | 0.065 | 0.060 through 0.065 |

| 13 | 0.095 | 0.087 through 0.097 |

| 14 | 0.083 | 0.075 through 0.085 |

| 8 | 0.165 | 0.157 through 0.167 |

| 7 | 0.18 | 0.175 through 0.185 |

| Pipe Size in Inches | Pipe Schedule | 500 | 100 | 300 | 200 | 400 | 600 | 700 | 650 | 750 |

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 40 | 1014 | 1531 | 1187 | 1321 | 1091 | 967 | 919 | 938 | 909 |

| 80 | 1466 | 2213 | 1715 | 1909 | 1577 | 1397 | 1328 | 1355 | 1314 | |

| 160 | 2386 | 3601 | 2791 | 3106 | 2566 | 2273 | 2161 | 2206 | 2138 | |

| 1 1/2 | 40 | 1496 | 2257 | 1750 | 1947 | 1608 | 1425 | 1354 | 1383 | 1340 |

| 80 | 2108 | 3182 | 2466 | 2744 | 2267 | 2009 | 1909 | 1949 | 1889 | |

| 160 | 3060 | 4619 | 3580 | 3984 | 3291 | 2916 | 2772 | 2829 | 2743 | |

| 2 | 40 | 1260 | 1902 | 1474 | 1640 | 1355 | 1201 | 1141 | 1165 | 1129 |

| 80 | 1820 | 2747 | 2129 | 2369 | 1957 | 1734 | 1648 | 1682 | 1631 | |

| 160 | 2980 | 4499 | 3486 | 3880 | 3205 | 2840 | 2699 | 2755 | 2671 | |

| 8 | 40 | 711 | 1073 | 832 | 926 | 765 | 678 | 644 | 657 | 637 |

| 80 | 1121 | 1692 | 1311 | 1459 | 1205 | 1068 | 1015 | 1036 | 1005 | |

| 160 | 2103 | 3175 | 2460 | 2738 | 2262 | 2004 | 1905 | 1944 | 1885 | |

| 6 | 40 | 808 | 1219 | 945 | 1052 | 869 | 770 | 732 | 747 | 724 |

| 80 | 1267 | 1913 | 1483 | 1650 | 1363 | 1208 | 1148 | 1172 | 1136 | |

| 160 | 2179 | 3289 | 2549 | 2836 | 2343 | 2076 | 1973 | 2014 | 1953 | |

| 1 | 40 | 2019 | 3048 | 2362 | 2629 | 2171 | 1924 | 1824 | 1867 | 1810 |

| 80 | 2791 | 4213 | 3265 | 3634 | 3002 | 2659 | 2528 | 2580 | 2501 | |

| 160 | 4068 | 6140 | 4759 | 5296 | 4375 | 3876 | 3684 | 3761 | 3646 | |

| 3 | 40 | 1196 | 1806 | 1400 | 1558 | 1287 | 1140 | 1084 | 1106 | 1072 |

| 80 | 1691 | 2553 | 1979 | 2202 | 1819 | 1612 | 1532 | 1564 | 1516 | |

| 160 | 2544 | 3840 | 2976 | 3312 | 2736 | 2424 | 2304 | 2352 | 2280 | |

| 5 | 40 | 889 | 1342 | 1040 | 1158 | 956 | 847 | 805 | 822 | 797 |

| 80 | 1312 | 1981 | 1535 | 1709 | 1411 | 1250 | 1189 | 1213 | 1176 | |

| 160 | 2262 | 3414 | 2646 | 2945 | 2433 | 2155 | 2049 | 2091 | 2027 | |

| 10 | 40 | 645 | 974 | 755 | 840 | 694 | 615 | 584 | 596 | 578 |

| 80 | 1066 | 1609 | 1247 | 1388 | 1147 | 1016 | 966 | 986 | 956 | |

| 160 | 2085 | 3147 | 2439 | 2714 | 2242 | 1986 | 1880 | 1927 | 1868 |

| STANDARD | UNS | WNR. | EN | JIS |

|---|---|---|---|---|

| SS 317 | S31700 | 1.4449 | - | SUS 317 |

| SS 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 317L |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| 317 | 0.08 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 14 | - |

| 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 15 | - |

| Density | 8.0 g/cm3 |

|---|---|

| Melting Point | 1454 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Physical Properties (Room Temperature) | ||

|---|---|---|

| Specific Heat (0-100°C) | 500 | J.kg-1.°K-1 |

| Thermal Conductivity | 14.6 | W.m -1.°K-1 |

| Thermal Expansion | 16.5 | mm/m/°C |

| Modulus Elasticity | 193 | GPa |

| Electrical Resistivity | 7.4 | μohm/cm |

| Density | 7.99 | g/cm3 |

| Stainless Steel 317 Condenser Tubes | Stainless Steel 317L Seamless Condenser Tubes |

| SS 317L Condenser Tubes | SS 317 Seamless Condenser Tubes |

| Condenser Tubes | SS 317L JIS Condenser Tubes |

| SS 317 DIN Condenser Tubes | ASME Stainless Steel 317 Condenser Tubes |

| ASTM A 249 Stainless Steel 317 Condenser Tubes | ASTM A 249 SS 317L Seamless Condenser Tubes |

Russia, Algiers, Antananarivo, Mbuji-Mayi, Subra al-Haymah, Nairobi, Bulawayo, London, Fez, Algeria, Maiduguri, Giza, Port Elizabeth, New Zealand, Johannesburg, Indonesia, Italy, Colombo, Ghana, Mozambique, Colombia, Qatar, Argentina, Zaria, Pretoria, Freetown, Khartoum, South Africa, Lagos, Bahrain, Turkey, Australia, Angola, United States, Douala, Kampala, Luanda, Hong Kong, Azerbaijan, Conakry, Kuwait, Casablanca, Tunisia, Abu Dhabi, Houston, Peru, Ethiopa, Kolwezi, Kaduna, Oman, UK, Israel, Dar es Salaam, Mogadishu, Alexandria, Saudi Arabia, Accra, Kinshasa, Abidjan, Yemen, Africa, Cairo, Cameroon, Brazil, Chine, Venezuela, Vietnam, Ouagadougou, Iran, Brazzaville, Addis Ababa, Dubai, Jordan, Thailand (Bangkok), Trinidad and Tobago, Tripoli, Cape Town, Uganda, Cyprus, Nigeria, Soweto, New York, Democratic Republic of the Congo, Omdurman, Mexico, Morocco, Egypt, Singapore, Iraq, Sri Lanka, Bamako, Harare, Durban, Kazakhstan, Yaoundé, Lubumbashi, Maputo, Germany, Ibadan, Benin, Malaysia, UAE, Sudan, Rabat, Lebanon, Port Harcourt, Canada, Kano.

Bhiwadi, Abu Dhabi, Hyderabad, Suryapet, Yemen, Ghana, Tadepalligudem, Tripura, Durban, Subra al-Haymah, Rabat, India, Conakry, Benin, Maharashtra, Uganda, Miryalaguda, Cairo, Angola, Benin, Port Harcourt, Nairobi, Cameroon, Antananarivo, Freetown, Jaipur, Lucknow, Hong Kong, Pune, Casablanca, Mumbai, Mozambique, Zaria, Kolkata, Ethiopa, Mizoram, Singapore, Karnataka, Bulawayo, Algeria, Ballia, Dar es Salaam, Venezuela, Cyprus, Mogadishu, Colombo, Surat, Port Elizabeth, Tripoli, Abidjan, Oman, New York, Bundi, Lagos, Thailand (Bangkok), Kano, Kolwezi, Addis Ababa, Buxar, Soweto, Cape Town, Baraut, Udgir, Betul, Kinshasa, Fez, Lubumbashi, Alexandria, Kerala, Ibadan, Khartoum, Manipur, Nagapattinam, Douala, Sadar, Democratic Republic of the Congo, Algiers, Bansberia, Jamalpur, Kaduna, Mbuji-Mayi, Bangalore, Maiduguri, Jordan, Morocco, Harare, Qatar, Ahmedabad, Lebanon, Chennai, Luanda, Kampala, Russia, Dakar, Maputo, Yaoundé, Accra, Johannesburg, Andhra Pradesh, Giza, Omdurman, Ambala, Puducherry, Ouagadougou, Bamako, Pretoria, Brazzaville, Muktsar, Delhi.

317 stainless steel pipe cost, stainless steel pipe 317 grade weight per meter, stainless steel 317 pipe schedule, stainless steel 317 seamless tubes, ss 317 tube price, jindal stainless steel 317 pipe price, 317l stainless steel pipe schedule, ss 317l erw pipe, 317l stainless steel pipe dimensions, stainless steel 317 pipe price per kg in india, 317l stainless steel tubing distributor, stainless steel pipe 317 grade, jindal ss 317 pipes price list, stainless steel 317 tube suppliers, stainless steel 317 instrumentation tube, 317 stainless steel pipe weight per foot, stainless steel 317 tube sizes, 317l stainless steel pipe pressure rating, stainless steel 317 tube pipe, ss 317 pipe price per kg in india, stainless steel 317 pipe weight, sus 317 stainless steel tube specifications, stainless steel 317 square tube exporter in india, stainless steel 317 pipe sizes, stainless steel 317l erw tube, stainless steel 317 pipe manufacturer, 317 stainless steel rectangular tubes stockist, stainless steel 317 efw pipe manufactures in mumbai, stainless steel 317 pipe thickness, stainless steel pipe aisi 317, stainless steel 317 pipe manufacturers india, stainless steel 317 pipe weight per meter, 317l schedule 10 stainless steel pipe.